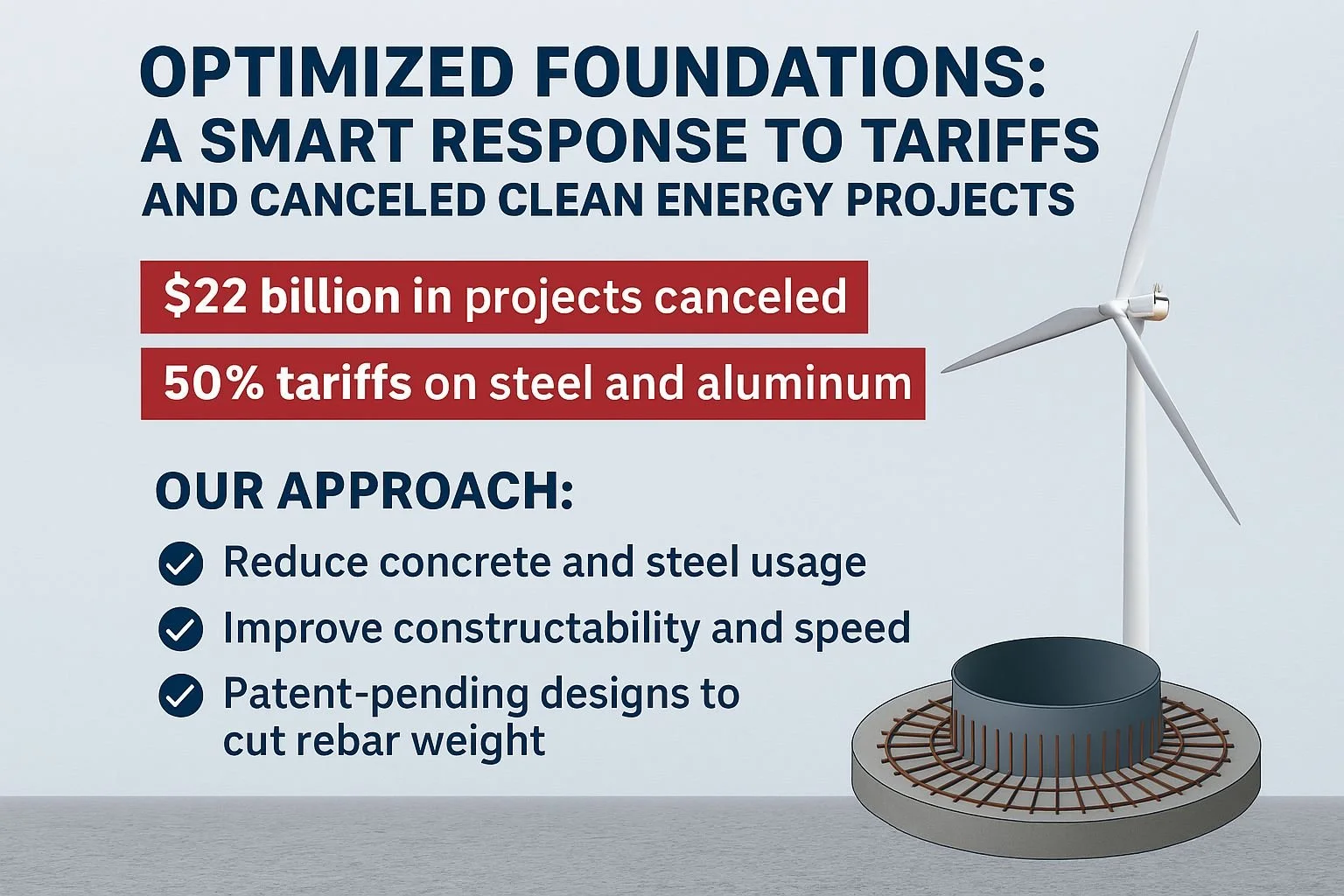

Optimized Foundations: A Smart Response to Tariffs and Canceled Clean Energy Projects

In a year marked by economic turbulence and policy reversals, the renewable energy sector is facing unprecedented headwinds. According to recent reports, over $22 billion in clean energy projects have been canceled in 2025 due to the rollback of federal incentives and regulatory uncertainty. These cancellations have disrupted development plans across wind, solar, and battery storage sectors—leaving developers scrambling for cost-effective solutions.

At Civil Renewables, Inc., we believe that engineering innovation—especially in foundation design—can help mitigate these setbacks. Our optimized foundation systems for utility-scale wind and solar projects are engineered to reduce material usage without compromising performance. In today’s tariff-heavy environment, that’s not just smart design—it’s a strategic advantage.

As of June 2025, the United States has officially doubled tariffs on imported steel and aluminum to 50% under Section 232 of the Trade Expansion Act. This dramatic increase has sent shockwaves through the construction industry, inflating costs and complicating procurement for developers nationwide.

Our foundation solutions directly address this challenge. For wind turbine generators, we use circular gravity-base foundations with radial reinforcement, which reduce concrete volume and steel waste. Compared to traditional octagonal designs, our approach allows for full-length rebar placement, fewer lap splices, and faster construction—all while using less material.

In addition, we are actively developing patent-pending technologies that will drastically reduce the weight of steel reinforcement in wind turbine foundations. These innovations are designed to maintain structural integrity and extending design life while slashing material costs—an essential breakthrough in the face of 50% tariffs.

For solar, our site-specific pile design minimizes overdesign through pile load testing and reduces the required steel—critical when every ton of imported steel carries a premium. These efficiencies are backed by advanced modeling tools, allowing us to simulate soil-structure interaction and optimize every design element.

As the industry grapples with canceled projects and rising material costs, our optimized foundations offer a path forward—one that supports clean energy deployment even when policy support falters. In a time when every dollar and every ton of steel counts, building smarter isn’t just good engineering—it’s essential strategy.